-

2103 Room NO.322 Xinggang One Road,Haicang District,Xiamen Fujian,China

Full-Automatic Solar C-Channel Steel Production Line

Table of Contents

Universal C-Channel Roll Forming for Solar Structures

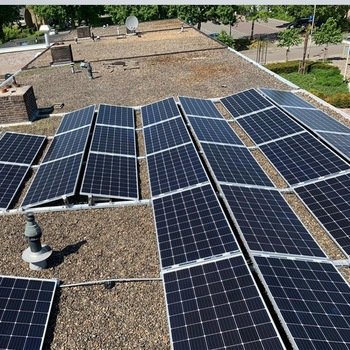

C-channel steel is a highly efficient, economical profile commonly used in a wide range of industrial and civil construction projects. Thanks to its optimized cross-sectional design, it offers excellent structural efficiency and load-bearing capacity. In solar energy applications, C-channel steel has become a fundamental material for solar mounting structures, providing critical support and stability.

C-Channel Steel and Solar Mounting Systems

Solar mounting systems are essential in photovoltaic (PV) power generation, designed to securely position, install, and support solar panels at optimal angles and orientations. C-channel steel is favored for solar racking due to its high strength, corrosion resistance, and excellent formability.

Our production line, crafted with strict quality standards, delivers high-precision C-channel steel, ensuring durability and performance for global solar projects. Particularly in regions like Japan, where stringent building codes require exceptional wind and snow load resistance, C-channel solar structures are extensively adopted.

- Learn more about our Ground Solar Mounting System.

- Explore C – Steel Ground Mount – Screw Pile Foundation.

- View C – Steel Ground Mount – Concrete Foundation.

Technical Principles of the C-Channel Roll Forming Line

Working Process Overview

The C-channel roll forming machine utilizes a cold bending technology. The steps are as follows:

1. Coil Unwinding and Initial Feeding

The steel coil is unwound via a decoiler and smoothly fed into the forming section.

2. Precision Roll Forming

The forming section, composed of precisely arranged rollers, gradually shapes the steel strip.

Each roller group incrementally bends and profiles the strip into the desired C-shape cross-section.

3. Servo-Controlled Cutting

Upon reaching the preset length, the servo-cutting unit operates seamlessly, ensuring a clean, burr-free cut without interrupting the production line.

4. Intelligent Control System

An advanced control panel adjusts parameters such as feed speed, roller pressure, and cutting length. This enables the production of C-channels in various sizes and thicknesses to meet diversified project needs.

Highlights of Our C-Channel Steel Production Line

★ High-Precision Servo Punching

- Equipped with high-accuracy transmission systems.

- Punching positioning is extremely precise.

- Material buffering after punching ensures smooth flow throughout the line.

★ Adjustable C-Channel Sizes

- Both base and web heights are infinitely adjustable via touch panel control, producing C-channels of customized dimensions on demand.

★ Non-Stop Servo Follow Cutting

- Utilizes a high-speed tracking shear mechanism.

- Cutting precision is enhanced with a ball screw-driven system.

★ Exceptional Production Efficiency

- Fully automatic continuous production.

- Ideal for mass manufacturing needs, such as for large-scale solar farms.

★ Versatile and Flexible Output

- A single machine adapts easily to produce a wide range of C-channel profiles, covering different building, warehouse, industrial facility, and solar energy applications.

★ Stable and Reliable Operation

- Robust frame structure made from premium steel.

- Advanced drive and control systems ensure smooth operation with minimal downtime.

★ User-Friendly Smart Operation

- Intelligent control interface.

- Basic training allows operators to manage and troubleshoot the machine with ease.

Applications Across the Solar Energy Sector

C-channel steel is widely used in:

- Ground-mounted solar systems (both screw pile and concrete foundations)

- Solar carports

- Agricultural PV systems (agrivoltaics)

- Floating solar installations

Example in Japan:

In regions like Hokkaido, where heavy snow loads are frequent, C-channel solar structures ensure superior strength and minimal maintenance issues over decades of operation.

Example in China:

Large-scale solar farms in Inner Mongolia utilize high-strength galvanized C-channels to withstand extreme wind conditions.