-

2103 Pokoj NO.322 Xinggang One Road, Haicang District, Xiamen Fujian, Čína

The Importance of Structural Analysis for Solar PV Mounting Systems

Table of Contents

Introduction: Why Calculations Are Not Optional

When we look at a solar farm or rooftop PV installation, the panels gleaming under the sun are impressive.

But hidden behind that visual success is a critical foundation: structural analysis.

Even the most promising solar projects can face serious structural issues — from gradual sagging and misalignment to sudden failures — if the underlying support system isn’t properly engineered.

In places like Japan and coastal regions of China, we’ve observed projects where small calculation errors, particularly in snow or wind load assumptions, ended up causing extensive structural damage and multi-million-dollar setbacks.

What Structural Analysis Protects Against

A proper structural calculation shields your project from:

- Wind damage: Ensuring panels don’t lift off during typhoons

- Snow overload: Preventing racks from collapsing under heavy snow loads

- Seismic shocks: Allowing structures to flex and survive earthquakes

In one case from Nagano Prefecture, Japan, insufficient snow load design led to multiple ground mounts failing within just two winters — an expensive lesson in why detailed analysis matters.

👉 Related System: Solární montážní systém na zemědělské půdě

Core Components of a Reliable Structural Analysis

1. Precise Environmental Load Inputs

Successful designs start with real-world data:

- Local design wind speeds (e.g., 32–42 m/s for coastal areas)

- Vertical snow accumulation expectations

- Seismic zone classifications

One-size-fits-all assumptions often lead to overdesign (wasting money) or underdesign (creating risks).

2. Smart Material and Section Selection

Choosing between pozinkovaná ocel, aluminum alloys, or hybrid structures isn’t just about strength.

It also involves:

- Corrosion resistance (especially near oceans)

- Weight (important for rooftop installations)

- Foundation loads

Example:

Using C-Steel Ground Mounts for inland projects and Aluminum Ground Mounts in high-corrosion coastal zones.

👉 Product Example: Hliníková zemní montáž - šroubový pilotový základ

3. Load Combinations and Safety Factors

Engineering design always considers “what if” scenarios:

- G + 0.7S (dead load + partial snow)

- G + W (dead load + strong wind)

- G + K (dead load + earthquake)

A structure must survive the worst-case combination, not just average conditions.

Real-World Project Lessons

- Overdesign adds 15-25% unnecessary cost.

- Underdesign risks complete project failure within 2–3 years.

- Accurate structural analysis saves on both materials and long-term maintenance.

In Fukui Prefecture, a ground-mounted PV system faced unexpectedly high snow loads. Thanks to solid structural calculations, the project only needed minor snow guards — no full rebuild was necessary.

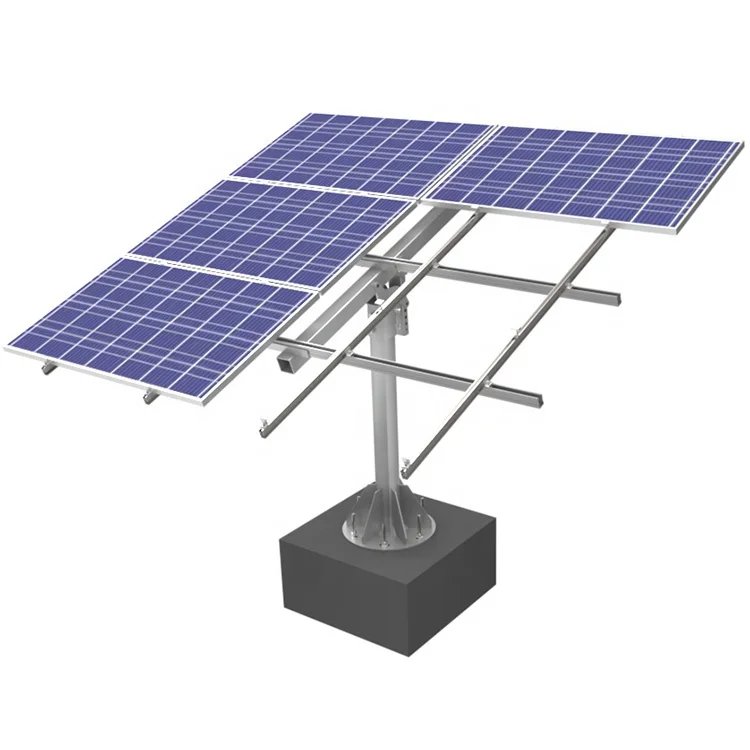

👉 Related Solution: Single Pole Ground Mounting System Manufacturer

Conclusion: Why Every Project Needs a Verified Structural Report

In solar energy, engineering resilience is engineering profit.

Spending time and resources on professional structural analysis pays off not just at commissioning — but for 25+ years of operational life.

A solid structure keeps your solar dream standing tall against the winds of reality.