-

2103 Zimmer NO.322 Xinggang One Road,Haicang District,Xiamen Fujian,China

Hot Dip Galvanized Solar Energy System Ground Screw

🕢 [ Füllen Sie das Formular aus und wir werden innerhalb von 24 Stunden antworten!]

📊 Comparison Table of Hot Dip Galvanized Ground Screws

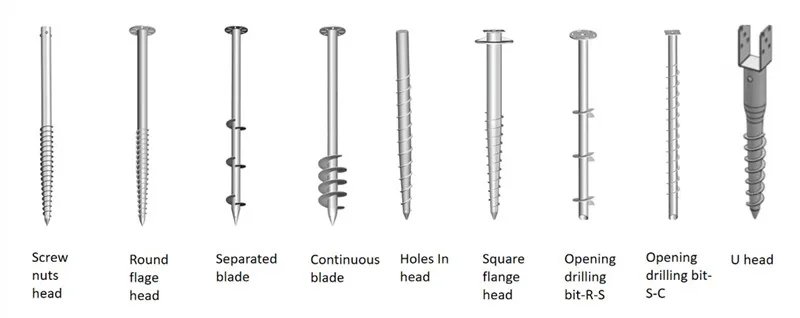

| Type | Name | Length (mm) | Diameter (mm) | Wall Thickness (mm) | Soil Type | Pull-out Force (KN) | Bearing Capacity (KN) | Torque (KN) | Application |

|---|---|---|---|---|---|---|---|---|---|

| Type 1 | Flange Blade Pile | 1200 / 2500 | 76–121 | 3.0–4.0 | Clay, Gobi, Gravel | 255 | 44 | 13 | Solar stations, fence bases, wood houses, signage |

| Type 2 | Flange Screw Threaded Pile | 1600 / 2000 / 3000 | 76–121 | 3.0–4.0 | Clay, Gravel, Gobi | 35 | 54 | 16 | Solar farms, billboard signs, fence, wooden houses |

| Type 3 | Double Blades Pile | 1500 / 2500 | 76–121 | 3.0–4.0 | Sandy, Soft Soil | 127 | 22 | 5.5 | Fixed solar mounts, small wooden houses |

| Type 4 | Three Blades Pile | 1500 / 2500 | 76–121 | 3.0–4.0 | Sandy, Soft Soil | 24 | 34 | 105 | Solar stations, simple housing, ad signage |

| Type 5 | Flange Helical Pile (U-Plate) | 1500 / 1800 / 2000 | 76–121 | 3.0–4.0 | Universal | — | — | — | Solar plants, wood housing, billboards |

| Type 6 | Small Helical Pile | 550 / 800 / 1000 | 62–76 | 1.8–2.5 | Clay, Gobi, Gravel | 22.6 | 36 | 95 | Solar base, fencing, cottages |

| Type 7 | Perfusion Pile | 1000 / 1300 / 1500 | 76–121 | 3.0–4.0 | Universal | — | — | — | Solar foundations, wood housing, ads |

| Type 8 | Tube Pile | 660 / 800 / 1200 | 76–121 | 3.0–4.0 | Universal | — | — | — | Solar structures, billboards, fences |

| Type 9 | Embedded Pile | 1300 / 1600 / 1800 | 76–121 | 3.0–4.0 | Clay, Gobi, Gravel | 22 | 20 | 9.6 | Solar plants, fencing, signage |

| Type 10 | Sand Area Embedded Pile | 1600 / 2000 / 2500 | 76–121 | 3.0–4.0 | Sandy Soils | 24 | 34 | 105 | Solar in sandy zones, ad signage, fences |

📐 Regular Sizes of Helical Piles (Customized Acceptable)

✅ Standard Round (Flange) Type

| Specification | Body Weight (kg) | Flange Weight (kg) | Blade Weight (kg) | Total Weight (kg) |

|---|---|---|---|---|

| 800×48×2mm | 1.81 | 1.50 | 0.30 | 3.61 |

| 800×60×2mm | 2.29 | 1.50 | 0.50 | 4.29 |

| 800×68×2mm | 2.60 | 1.50 | 0.50 | 4.60 |

| 800×76×2mm | 2.92 | 1.50 | 0.70 | 5.12 |

| 1000×48×2mm | 2.27 | 1.50 | 0.30 | 4.07 |

| 1000×60×2mm | 2.86 | 1.50 | 0.50 | 4.86 |

| 1000×68×2mm | 3.26 | 1.50 | 0.50 | 5.26 |

| 1000×76×2mm | 3.65 | 1.50 | 0.70 | 5.85 |

| 1200×48×2mm | 2.72 | 1.50 | 0.30 | 4.52 |

| 1200×60×2mm | 3.43 | 1.50 | 0.50 | 5.43 |

| 1200×68×2mm | 3.91 | 1.50 | 0.50 | 5.91 |

| 1200×76×2mm | 4.38 | 1.50 | 0.70 | 6.58 |

| 1200×76×3mm | 6.48 | 1.50 | 0.70 | 8.68 |

| 1400×76×2mm | 5.11 | 1.50 | 0.70 | 7.31 |

| 1400×76×3mm | 7.56 | 1.50 | 0.70 | 9.76 |

| 1600×68×3mm | 7.69 | 1.50 | 0.50 | 9.69 |

| 1600×76×2mm | 5.84 | 1.50 | 0.70 | 8.04 |

| 1600×76×3mm | 8.64 | 1.50 | 0.70 | 10.84 |

| 1600×89×3mm | 10.18 | 1.50 | 0.90 | 12.58 |

| 1800×76×2mm | 6.57 | 1.50 | 0.70 | 8.77 |

| 1800×76×3mm | 9.72 | 1.50 | 0.70 | 11.92 |

| 2000×76×2mm | 7.30 | 1.50 | 0.70 | 9.50 |

| 2000×76×2.75mm | 9.93 | 1.50 | 0.70 | 12.13 |

| 2000×76×3mm | 10.80 | 1.50 | 0.70 | 13.00 |

| 2000×76×3.5mm | 12.51 | 1.50 | 0.70 | 14.71 |

| 2000×89×3mm | 12.72 | 1.50 | 0.90 | 15.12 |

| 2000×89×3.5mm | 14.76 | 1.50 | 0.90 | 17.16 |

| 2500×76×3mm | 13.50 | 1.50 | 0.70 | 15.70 |

| 2500×76×3.5mm | 15.64 | 1.50 | 0.70 | 17.84 |

| 2500×89×3mm | 15.91 | 1.50 | 0.90 | 18.31 |

| 2500×89×3.5mm | 18.45 | 1.50 | 0.90 | 20.85 |

✅ Standard U Type

| Specification | Body Weight (kg) | U Head Weight (kg) | Blade Weight (kg) | Total Weight (kg) |

|---|---|---|---|---|

| 800×48×2mm | 1.81 | 1.00 | 0.30 | 3.11 |

| 800×60×2mm | 2.29 | 1.00 | 0.50 | 3.79 |

| 800×68×2mm | 2.60 | 1.00 | 0.50 | 4.10 |

| 800×76×2mm | 2.92 | 1.00 | 0.70 | 4.62 |

| 1000×48×2mm | 2.27 | 1.00 | 0.30 | 3.57 |

| 1000×60×2mm | 2.86 | 1.00 | 0.50 | 4.36 |

| 1000×68×2mm | 3.26 | 1.00 | 0.50 | 4.76 |

| 1000×76×2mm | 3.65 | 1.00 | 0.70 | 5.35 |

| 1200×48×2mm | 2.72 | 1.00 | 0.30 | 4.02 |

| 1200×60×2mm | 3.43 | 1.00 | 0.50 | 4.93 |

| 1200×68×2mm | 3.91 | 1.00 | 0.50 | 5.41 |

| 1200×76×2mm | 4.38 | 1.00 | 0.70 | 6.08 |

| 1200×76×3mm | 6.48 | 1.00 | 0.70 | 8.18 |

Usage Application

| City & parks | Docking post & Trestle stand |

| Fencing system | Flag Poles & Banners |

| Garden & Leisure | Sheds & Containers |

| Solar power systems | Solar racking systems |

| Street lamp & wooden house | Road & Traffic sign |

Advantages and Applications of Helical Piles

Helical piles are an innovative foundation solution composed of three main components: a hot-forged steel shaft, a helical blade, and a connecting flange plate. They are widely used across construction, energy, and agricultural sectors due to their efficiency and versatility.

✅ Key Advantages

1. Superior Structural Performance

- Helical piles are installed by rotating them into the ground, which minimizes soil disturbance and enhances stability.

- The helical blade design provides excellent uplift resistance and anchoring strength, making them ideal for both compression and tension loads.

2. Fast and Convenient Installation

- No excavation, no concrete, and no soil disposal required.

- Can be installed in a variety of weather conditions—rain, snow, or frozen ground—with minimal equipment.

- Easy to remove, relocate, and recycle, supporting sustainable construction.

3. Cost-Effective

- Compared to traditional concrete foundations, helical piles reduce labor, materials, and project duration.

- Simple installation requires only positioning and driving, lowering overall foundation costs.

🔧 Common Usage Scenarios

1. Building Construction

- Temporary Buildings

Ideal for site offices, worker accommodations, and mobile structures. Helical piles offer quick deployment, easy removal, and minimal site disruption. - Small Structures

Suitable for landscape pavilions, watchtowers, gazebos, and garden structures. They provide stable support and structural integrity on uneven or soft terrain.

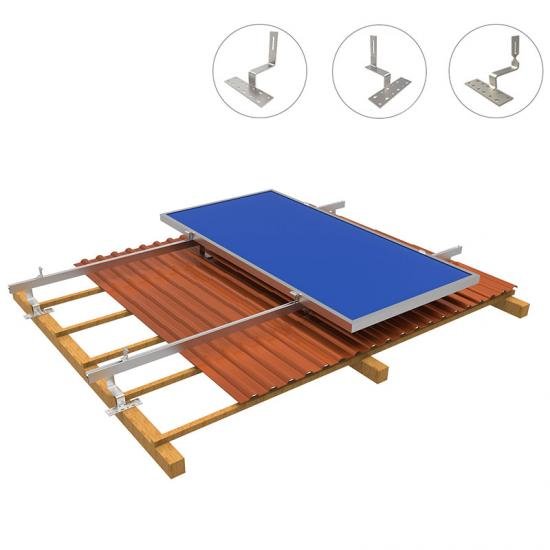

2. Solar Photovoltaic (PV) Installations

- Solar Power Plants

Widely used to secure PV mounting systems on the ground. Helical piles adapt to various soil types, speed up installation, and improve project timelines—especially in large-scale solar farms.

3. Transportation Infrastructure

- Traffic Signage and Safety Equipment

Used to anchor traffic signs, speed limit poles, and other roadside installations. Their stability ensures long-lasting support even in high-wind areas.

4. Telecommunications

- Communication Tower Bases

Provide a reliable foundation for telecom towers and antennas, particularly in remote or uneven terrain where traditional foundations are challenging to implement.

5. Agricultural Applications

- Greenhouse Foundations

Support greenhouse framing structures on different land types, reducing construction time and cost for agricultural operations. - Livestock Fencing

Combine with metal mesh fencing to create strong, fast-built enclosures for animal containment or land demarcation.

Helical piles are a sustainable, flexible, and efficient foundation solution for a wide range of industries. Their structural benefits, ease of installation, and reduced environmental impact make them a preferred choice for modern construction and renewable energy projects.

Hilfe-Center

Haben Sie eine Frage? Bitte prüfen Sie diese Frage und Antworten

Firstsolar verfügt über eine eigene Fabrik mit mehr als 80 qualifizierten und erfahrenen Mitarbeitern. Die Produktionslinie ist streng nach hohen Standards ausgerichtet und legt großen Wert auf Qualitätskontrolle und Inspektion.

Natürlich bieten unsere erstklassigen Produktionsingenieure, Techniker und unser Forschungs- und Entwicklungsteam unseren Kunden innovative Designs und zuverlässige Lösungen, die auf mehr als 8 Jahren Erfahrung basieren.

Ja, Firstsolar bietet seit mehr als 10 Jahren OEM-Service, Design-Service und Käufer-Label-Service.

Ja, die Produkte von Firstsolar sind von lSo, sGS, TUV und AS/NZS 1170.2 zertifiziert worden.

Es hängt von der tatsächlichen Bestellmenge und Ihren speziellen Anforderungen ab. Im Allgemeinen wird es 1-2 Wochen sein.

Liegt der Gesamtbetrag unter US$5000, benötigen wir 100% im Voraus; liegt der Gesamtbetrag überUS$5000, benötigen wir30%T/T im Voraus