-

2103 Room NO.322 Xinggang One Road,Haicang District,Xiamen Fujian,China

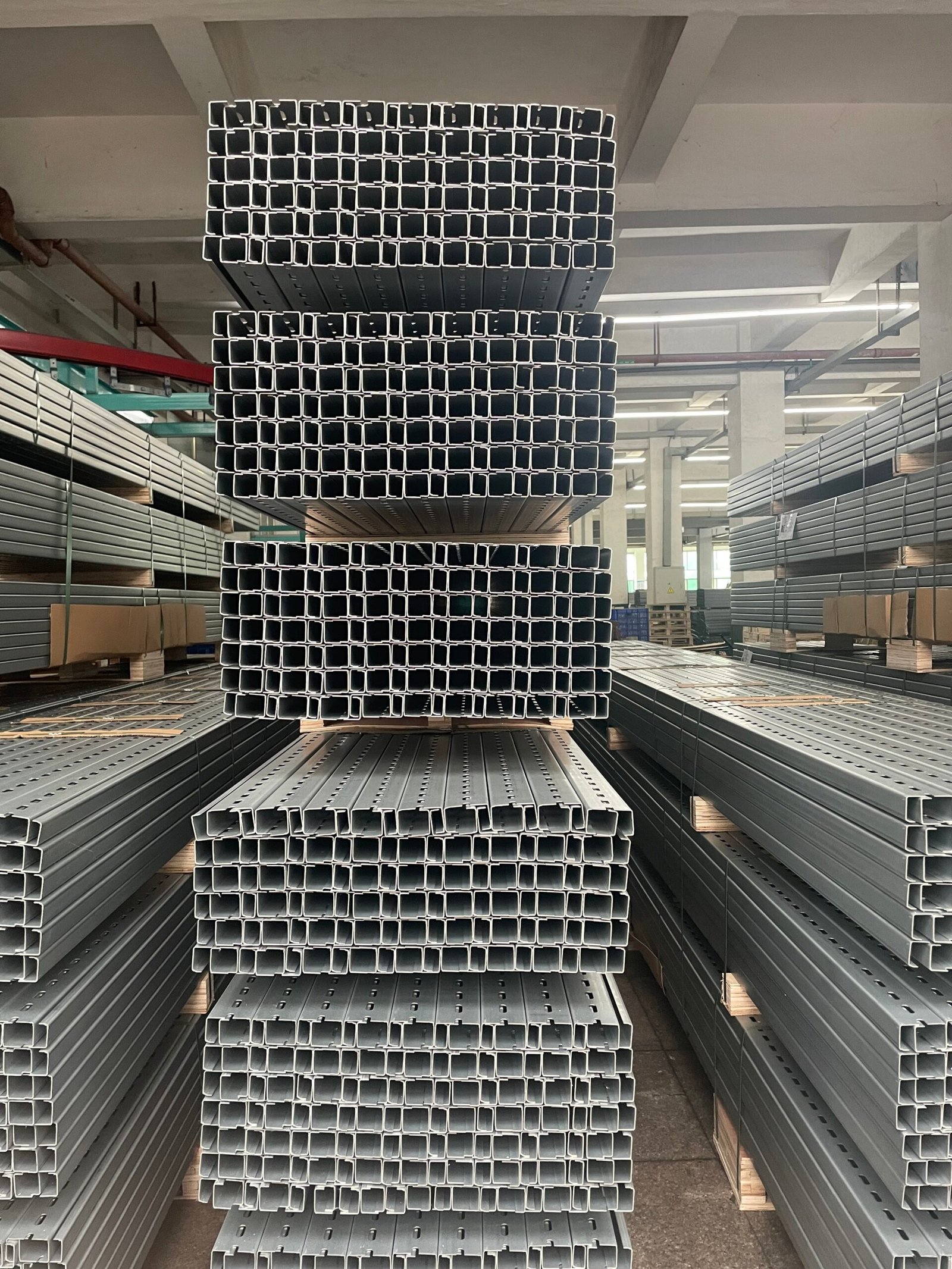

Zinc-Aluminum-Magnesium Plates in Photovoltaic Mounting Systems: Advantages and Future Outlook

With the growing global demand for clean energy, the photovoltaic (PV) market has entered an unprecedented phase of development. As a crucial component of PV systems, the choice of material for mounting structures directly affects the system’s stability, durability, and cost-effectiveness. Zinc-aluminum-magnesium (Zn-Al-Mg) plates have emerged as an ideal choice for manufacturing PV mounting systems due to their excellent corrosion resistance, high strength, and superior processing capabilities. As PV installation capacity continues to grow, the demand for Zn-Al-Mg plates is also increasing rapidly.

Table of Contents

Performance Advantages of Zinc-Aluminum-Magnesium Plates

The widespread application of Zn-Al-Mg plates in the PV industry is largely due to their multiple performance advantages.

1. Outstanding Corrosion Resistance

- High Corrosion-Resistant Coating: Zn-Al-Mg plates are coated with a layer of zinc-aluminum alloy, which enhances corrosion resistance. This coating performs exceptionally well in harsh environments, such as humid and saline conditions, significantly improving the service life of components like PV mounting structures.

- Self-Healing Property: When cut or scratched, Zn-Al-Mg plates form a protective layer (water-zinc mineral) through oxidation, which encapsulates rust and prevents further corrosion. This self-healing ability ensures the plates remain durable during processing and usage.

2. High Strength and Rigidity

- Strong Load-Bearing Capacity: Zn-Al-Mg plates exhibit high strength and rigidity, allowing them to withstand heavy loads and wind pressure. This ensures the stability and safety of the entire PV system.

- Lightweight Design: Compared to traditional steel, Zn-Al-Mg plates are lighter yet strong. This characteristic reduces the transportation, installation, and maintenance costs of PV systems.

3. Excellent Processing Capabilities

- Easy to Form: Zn-Al-Mg plates possess good plasticity and workability, making them easy to shape through deep drawing, bending, and cutting. This flexibility enhances efficiency in the manufacturing of PV mounting structures.

- Superior Welding Performance: The welding performance of Zn-Al-Mg plates is also excellent, making them suitable for the welding requirements of complex PV system structures.

4. Environmental and Energy Efficiency

- Eco-friendly Production Process: Compared to traditional hot-dip galvanizing processes, the production of Zn-Al-Mg plates is more environmentally friendly, reducing the use of chemicals and the environmental pollution associated with the production process.

- Long-Term Benefits: Due to their superior corrosion resistance and high strength, Zn-Al-Mg plates help reduce the need for replacements and maintenance over time. This not only lowers the overall cost of PV systems but also reduces resource waste and environmental impact.

5. High Cost-Effectiveness

- Lower Production Costs: Zn-Al-Mg plates are processed using continuous galvanizing techniques, which reduce post-processing and transportation costs. Additionally, the reduction in material costs and improved manufacturing efficiency lower the production costs of PV mounting components.

- Improved Economic Efficiency: The extended lifespan and stability provided by Zn-Al-Mg plates enhance the long-term economic benefits and return on investment for PV projects.

Future Outlook for Zinc-Aluminum-Magnesium Plates

Zn-Al-Mg plates have vast potential in the PV sector, primarily driven by the following factors:

1. Growing Market Demand

- Rapid Development of the PV Industry: In the context of global energy transition, the PV industry has become a leader in clean energy, achieving remarkable results. The domestic PV market continues to grow, with new installation capacities reaching historic highs. As a key component of PV systems, the demand for PV mounting structures is increasing.

- Policy Support: Governments around the world are promoting renewable energy and have implemented a series of policies to encourage the development of the PV industry, such as subsidies, favorable electricity pricing, and easier grid access. These policies provide a stable environment for the industry’s growth, which will further drive the use of Zn-Al-Mg plates in PV applications.

2. Expansion of Application Areas

- Ground-Mounted PV Power Stations: Zn-Al-Mg plates are widely used in large-scale ground-mounted PV power stations. Their excellent performance ensures long-term stability even in harsh environments, ensuring high efficiency for PV systems.

- Distributed PV Systems: As distributed PV systems continue to develop, Zn-Al-Mg plates are increasingly being used in rooftop and wall-mounted installations. The lightweight design and high strength make them ideal for a variety of building structures and installation environments.

- Special Environment PV Systems: PV systems in challenging environments, such as water-surface or desert installations, require higher-performance mounting structures. Zn-Al-Mg plates, with their exceptional corrosion resistance and strength, are an ideal choice for these specialized systems.

3. Technological Innovation and Upgrades

- Improvements in Production Techniques: As production technologies continue to advance, the performance of Zn-Al-Mg plates will improve. For instance, optimizing the hot-dip galvanizing process and enhancing coating uniformity can further boost corrosion resistance and mechanical properties.

- Product Diversification: With the continuous evolution of market demands, Zn-Al-Mg plates will be developed in more diversified forms. Customizable plates with different specifications and performance characteristics will meet the varied needs of the market.

As the PV industry grows and market demand rises, Zn-Al-Mg plates will play an increasingly important role in photovoltaic systems due to their outstanding performance characteristics and wide range of applications.