-

2103 Room NO.322 Xinggang One Road,Haicang District,Xiamen Fujian,China

5MW Solar Roof Mounting Project Construction Organization Design

Table of Contents

Project Overview and Characteristics

1. Basic Project Information

- Installed Capacity: 5MW (divided into three grid connection points of 2MW, 2MW, and 1MW)

- Installation Location: Industrial park rooftops (approximately 80% metal roofing and 20% concrete roofing), with a usable area of about 52,000 m²

- Module Type: 550W monocrystalline bifacial modules (9,100 units), with a tilt angle of 10°–15°

- Inverter Configuration: String inverters (50kW × 90 units)

2. Key Challenges

- Decentralized rooftops and complex ownership: Requires coordination among five different property owners.

- Reinforcement and waterproofing of metal roofing

- Grid connection: Must align with the power utility’s approval process for connection points.

Overall Deployment and Objectives

1. Organizational Structure

- Project Management Office: Includes one project manager, one technical lead, and one safety supervisor.

- Construction Teams: Divided into three working groups (module installation team, electrical construction team, and commissioning support team).

2. Key Milestone Targets

| Phase | Duration | Deliverables |

|---|---|---|

| Start-up Prep | 10 days | Construction plan approval, materials entry filing completed |

| Foundation Work | 25 days | Rooftop reinforcement completed, bracket bases embedded |

| Bracket & Module Installation | 45 days | All modules installed, tilt angle error ≤ 1° |

| Electrical Work | 30 days | DC-side insulation resistance > 1MΩ |

| Grid Connection Acceptance | 15 days | Approved by the utility company for grid connection |

3. Construction Master Plan Layout

- Materials Storage Area: Includes a temporary shelter for modules (protected from rain and dust) and a cable reel storage zone.

- Fabrication Area: Dedicated space for bracket cutting and welding (with dust removal equipment).

- Temporary Power Supply: Three 250kVA box-type transformers connected to the owner’s low-voltage distribution cabinet.

Construction Plan by Sub-Project

1. Rooftop Structural Treatment

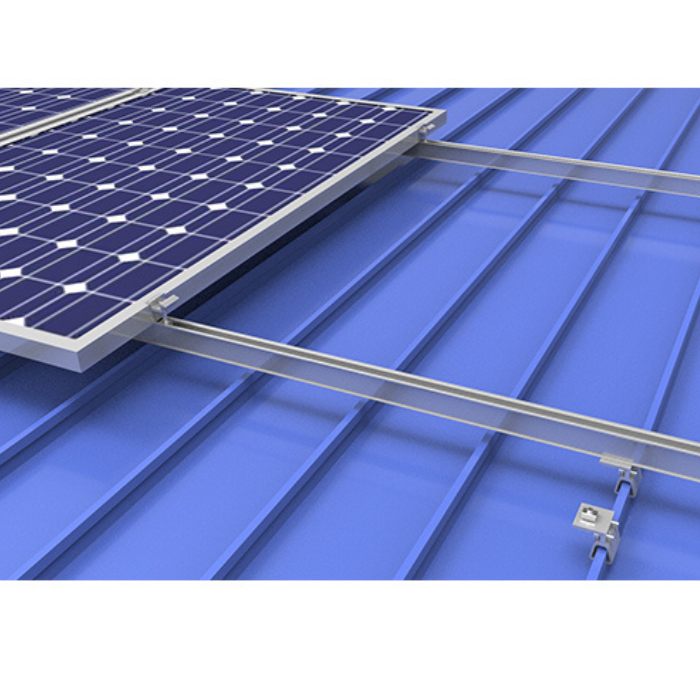

- Metal Roof Reinforcement:

- Utilize specialized roof clamps (model “CT-3”) to fix the support brackets, arranged at 1.5m intervals along each purlin span.

- For areas showing signs of rust, apply an epoxy zinc-rich primer (thickness ≥ 80µm).

- Concrete Roof Waterproofing:

- Embed chemical anchor bolts and then apply polyurethane waterproof coating (thickness 2mm, elongation ≥ 450%).

2. Support Brackets and Module Installation

- Bracket Installation:

- Tolerance Control: Vertical deviation of columns ≤ 3mm/m; horizontal beam spacing deviation ±5mm.

- Grounding for Lightning Protection: Use 40×4mm galvanized flat steel with continuous welding (ground resistance ≤ 4Ω).

- Module Installation:

- Fixed using mechanical clamps, with horizontal/vertical spacing deviations ≤ 2mm.

- Important: Avoid stepping on the metal roof’s raised wave crests (workers may only walk in the wave troughs).

3. Electrical System Construction

- DC Side Construction:

- String Design: 22 modules per string (22 × 550W = 12.1kW), each inverter connects 9–10 strings.

- Cable Selection: PV1-F 4mm² photovoltaic cable (UV-resistant, operating temperature from –40°C to 120°C).

- AC Side and Grid Connection:

- Each inverter’s AC output is fitted with a surge protector (Iimp ≥ 15kA).

- The grid connection cabinet includes anti-islanding protection and an online power quality monitoring device.

Resource Allocation Plan

1. Workforce Plan (Peak Period)

| Role | Headcount | Scope of Work |

|---|---|---|

| Bracket Installers | 30 people | Bracket measurement, cutting, and reinforcement |

| Module Installers | 40 people | Module handling, leveling, and mounting |

| Electricians | 15 people | DC wiring, inverter installation and commissioning |

| General Laborers | 20 people | Materials handling, safety supervision |

2. Machinery and Equipment List

| Equipment Name | Model/Specification | Quantity |

|---|---|---|

| Articulated Aerial Work Platform | GTZZ18 (18m) | 3 units |

| Specialized PV Clamp Tool | YKJ-5 | 10 units |

| DC Insulation Tester | Fluke 1507 | 5 units |

| Laser Level | Leica LINO L2 | 6 units |

3. Materials Delivery Plan

- First Batch (5 days after project start): Steel for brackets, chemical anchor bolts, and grounding flat steel.

- Second Batch (20 days after project start): Photovoltaic modules, inverters, and DC cables.

- Third Batch (50 days after project start): Grid connection cabinet and monitoring system equipment.

Quality and Safety Management

1. Quality Standards

- Mandatory National Codes:

- Code for Construction of Photovoltaic Power Station (GB 50794-2012)

- Code for Design of Lightning Protection of Buildings (GB 50057-2010)

- Key Performance Indicators:

- String current dispersion ≤ 3% (sample-check 10% with I-V curve tester).

- Maximum roof membrane deformation ≤ 5mm (observed 72 hours after completion).

2. Safety Management Measures

- Control of High-Risk Operations:

- Work at Height: 100% use of double-hook safety harnesses (lifelines installed on rooftop).

- Hoisting Operations: Demarcate a restricted area; signal operators must be certified.

- Emergency Preparedness:

- Heatstroke Treatment: Provide Huoxiang Zhengqi liquid and sunshades on site (no outdoor work from 11:00–15:00 on high-temperature days).

- Electrical Fire: Equip each work area with two 5kg dry powder fire extinguishers.

Progress Assurance Measures

1. Dynamic Adjustment Mechanism

- Daily Morning Meeting: Summarize previous day’s progress deviation and adjust priorities for the current day’s tasks.

- Weather Alerts: Obtain weather forecasts three days in advance; shift to indoor electrical wiring on rainy days.

2. Schedule Optimization Strategies

- Parallel Construction: Execute rooftop reinforcement and pre-assembly of brackets simultaneously (pre-assembly ratio up to 60%).

- Modular Transportation: Transport modules by string sets to reduce on-site sorting time.

Acceptance and Handover

1. Staged Acceptance

| Acceptance Stage | Participants | Document Package |

|---|---|---|

| Hidden Works Acceptance | Owner / Supervisor / Constructor | Waterproof layer inspection report, ground resistance test |

| Pre-Grid Connection Acceptance | Utility Company / Third-Party Testing Agency | Anti-islanding test report, power quality report |

2. Warranty Services

- Module Warranty: 12-year product warranty; performance degradation ≤ 20% over 25 years.

- Intelligent O&M: Deploy a monitoring platform (automatic fault dispatch, 2-hour response time).

References:

- Construction Master Plan Layout

- Rooftop Load Calculation (including structural institute approval)

- Grid Connection Electrical Diagram

Note: This plan should be adjusted based on the actual rooftop survey results (e.g., metal roof thickness, purlin spacing). If necessary, commission a third party to conduct load-bearing reviews.