-

2103 Room NO.322 Xinggang One Road,Haicang District,Xiamen Fujian,China

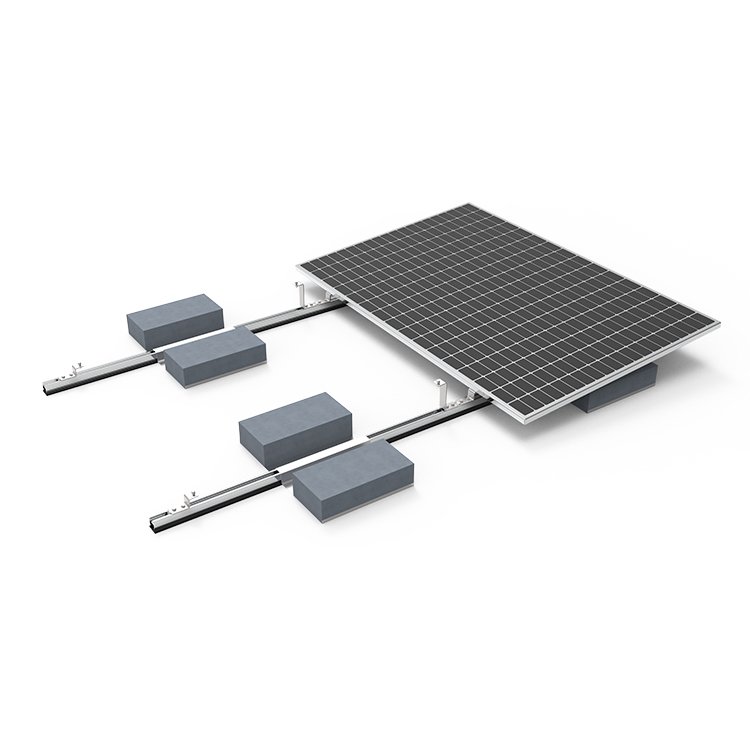

East-West Row Solar Ballasted Roof Racking System Manufacturer

Product Discription

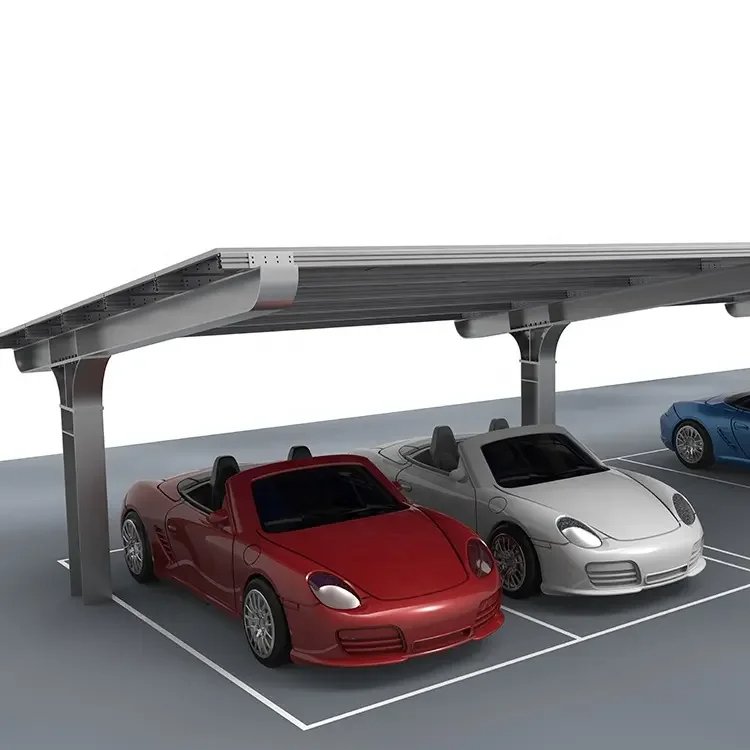

The East-West Row Solar Ballasted Roof Racking System is a solution for providing a robust, reliable, and efficient mounting solution for flat roof solar installations where roof penetration is undesirable or prohibited, especially for east-west roof layouts. This system employs a non-penetrating ballast design, ensuring the integrity of the roof membrane while delivering a secure and long-lasting PV array for east-west sunlight patterns.

Parameters

| Material: | Aluminum 6005-T5 & SUS 304 Stainless Steel & Zn-Al-Mg coated steel |

| Surface Treatment: | Anodized |

| Application: | Flat Rooftop |

| Tilt angle: | 5-15 degrees |

| Standard: | AS/NZS 1170 |

| Wind Load: | Below 60M/S |

| Snow Load: | Below 1.4KN/M2 |

| Certification: | ISO9001/CE/UL |

| Warranty: | 10 Years |

| Service Life: | 25 Years |

| Applicable Module: | Framed or Frameless |

Key Features & Benefits:

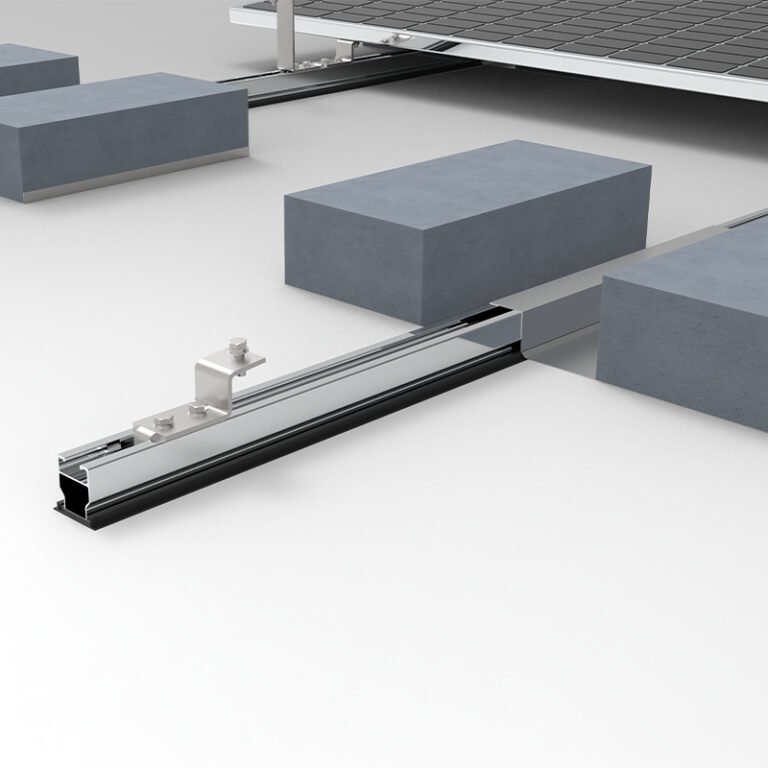

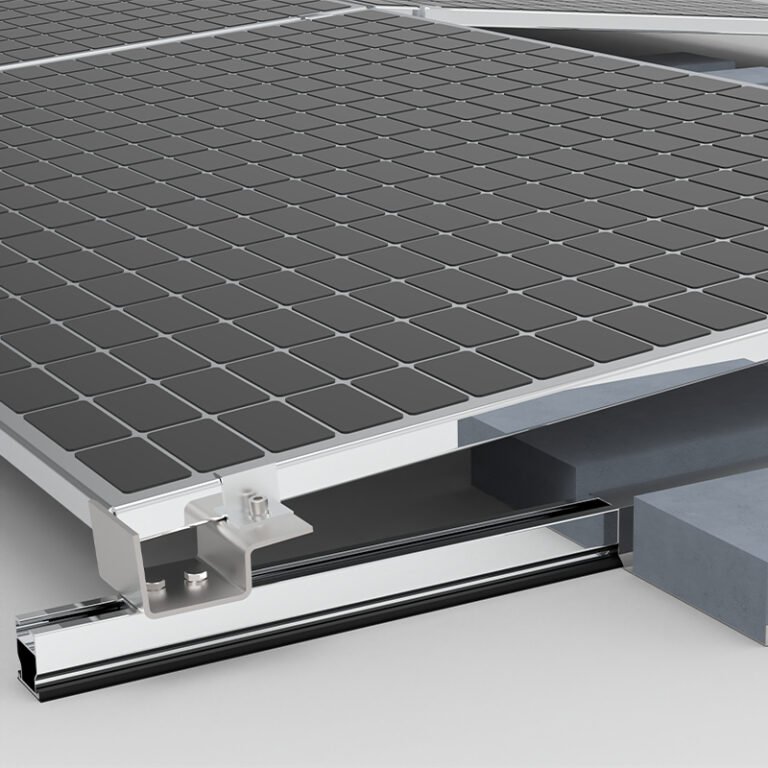

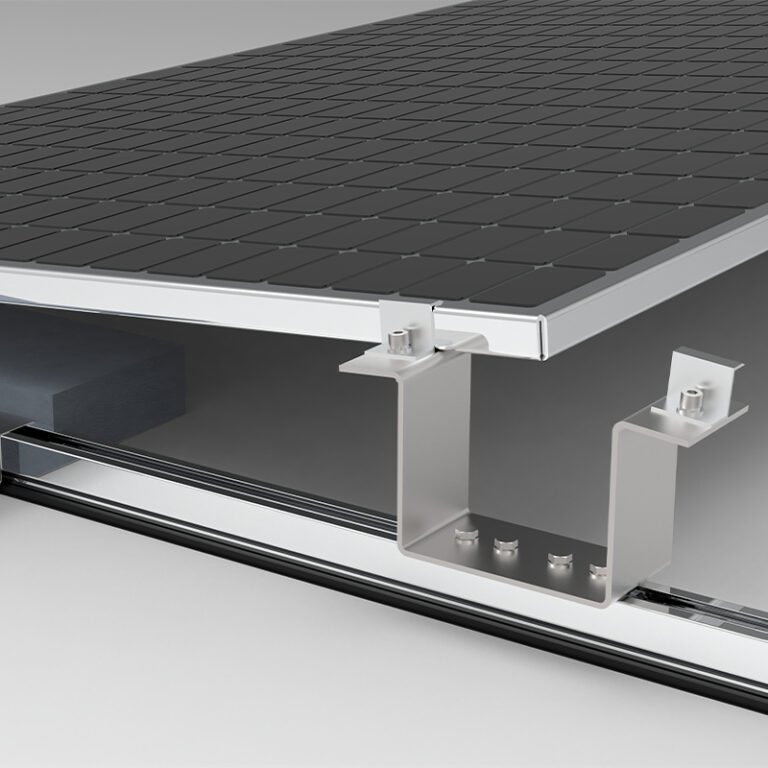

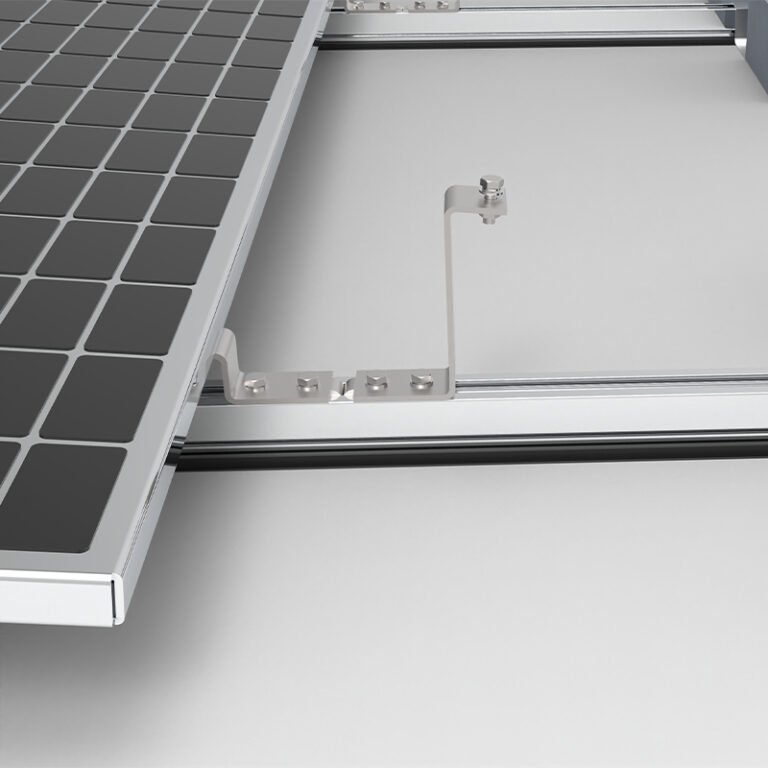

- Non-Penetrating Design: The system eliminates the need for drilling or fastening into the roof structure. Pre-fabricated aluminum rails form the structure, minimizing the risk of leaks, and reducing the complexity of the installation. Ballast weight (typically concrete blocks) is used to secure the array, protecting the roof and creating a long-lasting solution.

- East-West Orientation: This system is specifically configured for an east-west facing module orientation. Unlike traditional north-south facing systems, an east-west configuration provides a more consistent energy output over the course of the day, capturing both morning and afternoon sun. This orientation maximizes energy capture and power yield and makes the most effective use of available roof space. This results in improved overall system performance compared to traditional north-south mounting.

- Optimized Aluminum Structure: Crafted from high-grade aluminum, the system delivers a lightweight yet strong mounting platform for solar panels. The aluminum structure is corrosion-resistant, ensuring longevity and reducing maintenance needs. The lightweight nature makes it easier to handle and install compared to steel options.

- Simplified Installation: The modular design and pre-fabricated components drastically reduce the installation time and manpower needed, resulting in lower overall project costs and faster deployment.

- Integrated Cable Management: The system includes pathways for neat and secure cable management to minimize the risk of damage and improve system aesthetics.

- Versatile Compatibility: The racking system is compatible with a wide range of standard solar panel sizes and a variety of flat roof surfaces and membrane types. It is also designed to accommodate standard sized concrete blocks for ballasting.

- Wind and Load Performance: The system is engineered to withstand high wind loads and various weather conditions according to national and international building codes. The stable east-west configuration is inherently more stable, particularly compared to south-facing arrays.

- Reduced Shipping Costs: The lightweight aluminum structure, coupled with efficient stacking, provides reduced shipping costs.

Benefits for Solar Energy Professionals:

- Reduced Installation Time & Cost: The non-penetrating design and simplified assembly processes significantly cut installation time and labor costs.

- Increased Project Opportunities: The system’s suitability for roofs where penetration is prohibited opens new avenues for solar installations.

- Enhanced System Performance: The east-west orientation and efficient design maximize energy yield, translating to greater return on investment for clients.

- Reliable & Durable Solution: The system is designed for longevity and reliability, reducing maintenance requirements and ensuring customer satisfaction.

- Aesthetically Pleasing: The low profile of the array is very discreet, improving the building’s aesthetics compared to higher profile mounts.

In conclusion, the East-West Aluminum Ballasted Flat Roof Solar Racking System is a smart choice for installations needing high performance, fast and easy deployment, minimal roof disturbance, and long-lasting reliability. It is a perfect fit for a variety of flat roof installations and provides the highest energy yield for your customers while maintaining the integrity of the building’s structure.”

Revised & Expanded FAQ: East-West Aluminum Ballasted Flat Roof Solar Racking System

Q: Is this system suitable for all types of roofs?

A: This system is primarily designed for flat roofs and is particularly well-suited for East-West oriented configurations to maximize solar energy production. While it can be adapted to some other roof types (such as low-slope roofs), this is subject to a thorough assessment of the roof’s load-bearing capacity, structural integrity, and the specific roof membrane. A professional site evaluation is always recommended to determine suitability.

Q: Do I need specialized skills to install this solar roof mounting system?

A: Yes, installation by an experienced solar professional or qualified installer is highly recommended. Proper installation is crucial to ensure the system’s safety, performance, and longevity. Improper installation can lead to reduced system efficiency, structural issues, and void warranties. Installers should be familiar with solar racking systems, ballasted installations, and safe working practices on roofs.

Q: How often do I need to maintain the system after installation?

A: Routine maintenance is important for the long-term performance and reliability of the solar system. Maintenance intervals depend on factors such as the local environment, weather conditions, and the specific components used. Generally, it’s recommended to conduct a visual inspection of the system at least once a year. This should include checking the racking structure, ballast, wiring, and panel condition. We also suggest periodic electrical testing as part of an ongoing maintenance program. More frequent inspections may be necessary in harsh weather conditions.

Q: How resistant is this system to severe weather conditions?

A: This system is engineered to withstand a wide range of severe weather conditions, including high winds, heavy snow loads, and extreme temperatures. The stable, low-profile design is inherently more resilient to wind uplift compared to higher profile mounts. The aluminum structure provides excellent corrosion resistance. However, it’s critical that the system is installed according to the manufacturer’s instructions and local building codes to ensure it can withstand these conditions safely. Proper ballast weight calculation is also important for optimal performance in severe weather.

Q: Does the installed solar system need to be removed if the roof needs to be repaired?

A: One of the benefits of a ballasted system is its flexibility during roof maintenance. Typically, it is not necessary to remove the entire solar system for minor roof repairs. The system can be easily moved or shifted by qualified professionals as needed to facilitate roofing work. However, the specific procedure will depend on the type and extent of roof repair required. Always consult with a roofing and solar professional to ensure that the solar system and the roof are treated properly during roof repairs.

Q: What is the maximum load capacity of the system?

A: The maximum load capacity of the system is determined by several factors, including the specific weight of the concrete ballast blocks used, the roof’s structural load-bearing capacity, and applicable local building codes. It’s essential to perform a professional roof load assessment prior to installation to ensure it can safely accommodate the system’s weight and the additional weight imposed by environmental factors like snow or wind. This calculation is specific to each site and should be performed by qualified personnel. Incorrect weight calculations can lead to structural issues and should be avoided.

Q: Can this system be easily expanded to add more solar panels in the future?

Q: Can this system be easily expanded to add more solar panels in the future?

A: Yes, the modular design of this system allows for relatively easy expansion if your energy needs increase in the future. Adding more panels would require an evaluation of whether the existing racking can accommodate the additional load, and may require additional ballast. It is often a straightforward process since the racking is modular and designed for additional panel attachment, however, we recommend consulting with a qualified professional before making any changes.

Q: What is the warranty for this racking system?

A: Our racking system comes with a standard manufacturer’s warranty for defects in materials and workmanship for [insert warranty period]. Please note that the warranty does not cover damage caused by improper installation, natural disasters, or unauthorized modifications. Specific warranty details will be provided along with the purchase of the system. Always retain warranty information and follow manufacturer recommendations for upkeep and maintenance.

Help Center

Have a query? Please check this question and answers

Firstsolar has own factory with more than 80 skilled and experienced workers,the productionline is strictly in accordance with high standards and attach great importance to quality controland inspection.

Of course, our first-class production engineers, technicians and R & D team offer innovativedesign and reliable solution to customers based on more than 8 years of experiences.

Yes,Firstsolar has provided OEM service,design service and buyer label service for more than10 years.

Yes the products of Firstsolar have been certified by lSo, sGS,TUVand AS/NZS 1170.2.

It depends on actual order quantity and your special requirements. Generally, it will be 1-2weeks.

lf total amount is less than US$5000, we need 100% in advance; if total amount is more thanUS$5000, we need30%T/Tin advance