-

2103 Room NO.322 Xinggang One Road,Haicang District,Xiamen Fujian,China

Ground-Mounted Solar Racking Systems: Key Features and Considerations

Table of Contents

If you’re planning a solar project and have open land available, a ground-mounted solar racking system is one of the most effective installation options. Commonly used in industrial and large-scale applications, this mounting type allows for flexible panel orientation and high energy yields.

This article outlines the components, materials, foundation types, and maintenance essentials to help you evaluate if a ground-mounted system is right for your project.

What Is a Ground-Mounted Solar Mounting System?

Ground-mounted systems are designed to be installed directly on open land, such as unused plots or fields. They feature adjustable tilt angles, enabling optimized sun exposure and efficient power generation.

Such systems are often used in utility-scale applications and are sometimes referred to as free-standing PV systems.

→ See Ground Solar Mounting System

Alternatives to Ground Mounting

While ground mounting is ideal for open land, other options are better suited to different property types:

- Metal Roof Mounting Systems: Suitable for factories and warehouses.

- Flat Roof Mounting Systems: Used on concrete or flat-roof buildings.

- Floating Solar Mounting Systems: Designed for ponds and water surfaces.

Each system type is selected based on the specific structure and environmental conditions.

System Structure Overview

A ground-mounted system is made up of two main elements:

- Racking Frame: The supporting structure for solar panels.

- Foundation: Anchoring elements that secure the structure to the ground.

These components are typically assembled on-site using pre-fabricated parts.

Common Materials Used

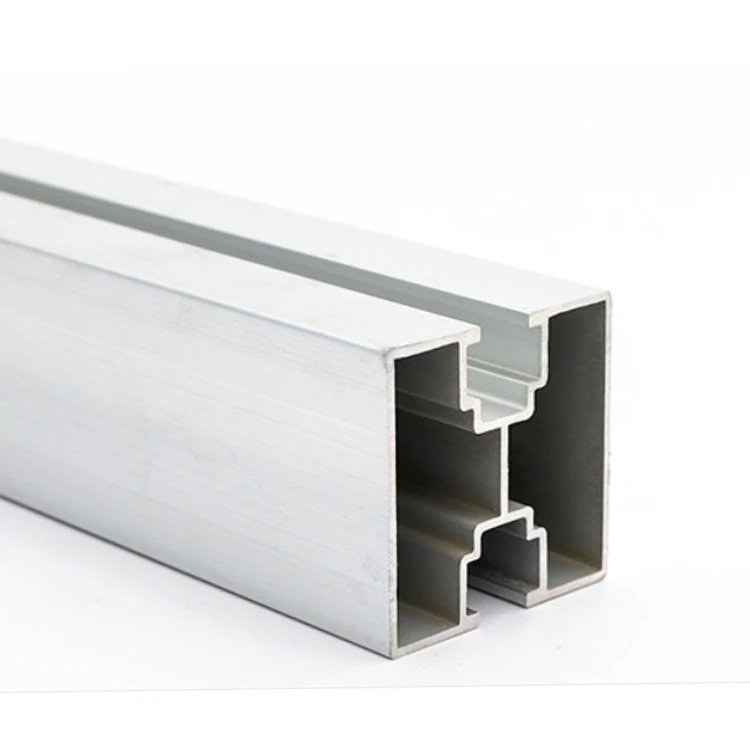

Aluminum

- Lightweight and easy to transport

- Corrosion-resistant, suitable for outdoor conditions

- High recyclability and lower long-term cost

- Ideal for both rooftop and ground applications

→ View Aluminum Ground Mount – Screw Pile Foundation

Stainless Steel

- Offers excellent durability and corrosion resistance

- Heavier and more difficult to process on-site

- Higher cost and not easily recyclable

Steel

- Strong and affordable

- Requires surface treatment (e.g., hot-dip galvanizing) to resist rust

- Heavier and harder to modify on-site

→ Explore C – Steel Ground Mount – Screw Pile Foundation

Foundation Types and Strength

Concrete Foundation

- Long lifespan and high stability

- Ideal for permanent installations

- Options:

- Strip Foundation

- Mat Foundation

- Block Foundation

→ Check Concrete Block Foundation

Pile-Driven Foundation

- Faster installation, lower cost

- Two main types:

- Screw Piles: Provide moderate strength with faster install

- Pipe Piles: Less resistance to wind uplift

Site Testing Before Installation

Pull-Out Strength Test

This test measures how well the foundation resists upward force from wind or soil shifts. It’s crucial for installations using angled mounts, which are more prone to uplift.

Soil Investigation

A proper geotechnical survey ensures that the ground is capable of supporting the structure without shifting or sinking. Common tools include Swedish Weight Sounding (SWS) tests.

Key Maintenance Considerations

Weed Management

- Periodic mowing and vegetation control are essential.

- Use herbicides or lay down blackout weed-control sheets.

- Consider taller posts to avoid ground vegetation interference.

Snow Load Considerations

- Install panels with tilt angles of 15°–40° to help snow slide off.

- Keep at least 50 cm clearance from the ground in low-snow areas and up to 100 cm in regions with heavy snowfall.

Choose the Right Partner for Long-Term Reliability

Ground-mounted solar systems offer efficient power generation and long-term reliability—but only when designed and installed correctly. At FirstSolar, we provide tailored solutions based on your site and budget, offering both aluminum and steel frame options, and multiple foundation types.

🔗 Explore More:

- Ramming Pile Ground Mounting System Manufacturer

- Single Pole Ground Mounting System Manufacturer

- Solar Mounting Accessories