-

中国福建省アモイ市海滄区興港一路322号2103室

Detailed Guidelines for Cast-in-Place Concrete Solar Mount Foundation Construction

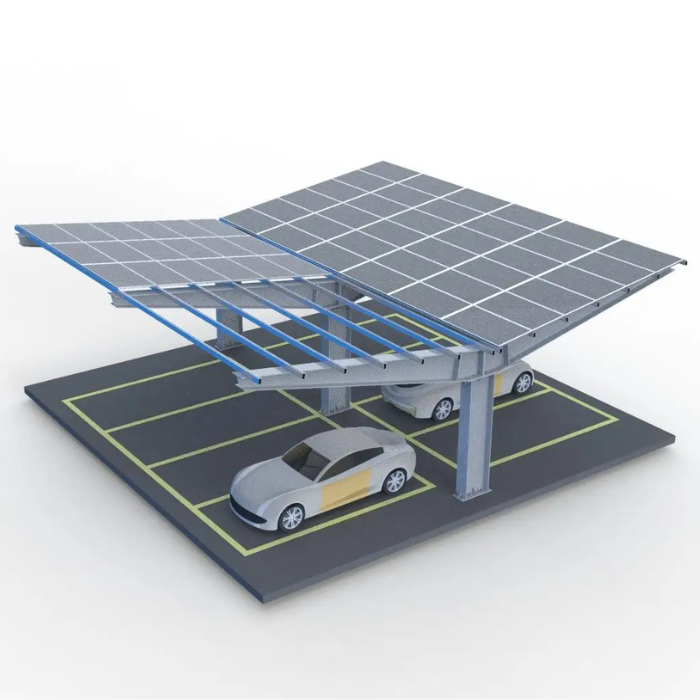

The construction of cast-in-place concrete foundations for solar mounting systems is a critical process to ensure the stability and long-term operation of photovoltaic (PV) plants. Just like laying a strong foundation for a building, every detail must be executed with precision. Let’s walk through the key steps and regulations in a clear, practical way.

Table of Contents

Preparation Before Construction

Thorough Site Inspection

Before starting the foundation work, it’s essential to inspect the excavation trenches carefully. Just like verifying the groundwork before building a house, you must ensure that the axis lines, trench dimensions, and bottom elevations fully meet the design specifications. Even small discrepancies can compromise stability.

Additionally, all loose soil, standing water, and debris inside the trenches must be completely removed. Otherwise, it’s like trying to build on quicksand — unstable and risky.

In Japan, solar power developers typically conduct meticulous base inspections, especially for projects installed on mountainous or uneven farmland where ground stability is crucial.

Pouring the Concrete Bedding

After inspection, immediately pour the bedding concrete. This layer acts like the “primer” for the main structure, providing a solid base for the upcoming work.

🔗 Related Product: Concrete Block Foundation for Solar Mounting

Concrete Pouring: Precision Matters

Inspection Before Pouring

Before pouring the main concrete, recheck the axis alignment, the formwork installation, and perform acceptance inspections for embedded steel bars and pre-buried components. These elements are like the “bones” of the foundation — misalignment or missing parts can seriously weaken the structure.

Continuous Pouring without Interruption

Whenever possible, pour the concrete for each foundation base continuously in one operation, similar to steaming buns without turning off the heat halfway. If pouring must pause and exceeds the initial setting time, you must properly treat the construction joints to prevent cracks.

For strip foundations, construction joints should be placed at structurally designated locations whenever possible, minimizing potential weak points.

Post-Pouring: Curing and Inspection

Surface Quality and Defect Management

Once the formwork is removed, inspect the appearance and dimensional tolerances of the concrete. It’s like checking homework for mistakes — any defects must be corrected according to acceptance standards.

Both the supervising engineer and construction team should participate in this inspection. Any exposed embedded metal parts must receive anti-corrosion treatment to prevent rust, which would weaken the foundation over time.

Proper Concrete Curing

Proper curing is like nurturing a young tree — it requires attention and water. Concrete should be cured until it reaches at least 70% of its design strength before installing solar mounting structures. Installing prematurely is risky; it’s like forcing a sapling to support heavy loads before it’s strong enough.

Construction Management: Quality Assurance by Division

Dividing Work into Inspection Batches

During construction, split the work into multiple inspection batches based on work shifts and construction segments. It’s similar to breaking a big exam into smaller sections for better quality control. Only when every small batch meets the standards can the entire foundation structure achieve high-quality results.

In Japanese mega solar projects (over 1MW), construction is carefully divided into daily inspection lots to maintain consistent quality.

結論

The construction regulations for cast-in-place concrete foundations are interconnected and vital. Each step impacts the overall stability and lifespan of the solar installation. By meticulously following these steps, we ensure that solar plants, like deeply rooted trees, can generate clean energy stably for decades.