-

2103 호실 322호 싱강 원 로드,하이창구,샤먼 푸젠,중국

Hot Dip Galvanized Solar Energy System Ground Screw

📊 Comparison Table of Hot Dip Galvanized Ground Screws

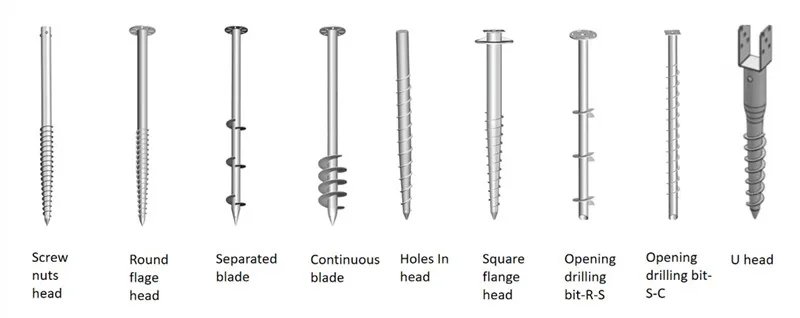

| Type | 이름 | Length (mm) | Diameter (mm) | Wall Thickness (mm) | Soil Type | Pull-out Force (KN) | Bearing Capacity (KN) | Torque (KN) | Application |

|---|---|---|---|---|---|---|---|---|---|

| Type 1 | Flange Blade Pile | 1200 / 2500 | 76–121 | 3.0–4.0 | Clay, Gobi, Gravel | 255 | 44 | 13 | Solar stations, fence bases, wood houses, signage |

| Type 2 | Flange Screw Threaded Pile | 1600 / 2000 / 3000 | 76–121 | 3.0–4.0 | Clay, Gravel, Gobi | 35 | 54 | 16 | Solar farms, billboard signs, fence, wooden houses |

| Type 3 | Double Blades Pile | 1500 / 2500 | 76–121 | 3.0–4.0 | Sandy, Soft Soil | 127 | 22 | 5.5 | Fixed solar mounts, small wooden houses |

| Type 4 | Three Blades Pile | 1500 / 2500 | 76–121 | 3.0–4.0 | Sandy, Soft Soil | 24 | 34 | 105 | Solar stations, simple housing, ad signage |

| Type 5 | Flange Helical Pile (U-Plate) | 1500 / 1800 / 2000 | 76–121 | 3.0–4.0 | Universal | — | — | — | Solar plants, wood housing, billboards |

| Type 6 | Small Helical Pile | 550 / 800 / 1000 | 62–76 | 1.8–2.5 | Clay, Gobi, Gravel | 22.6 | 36 | 95 | Solar base, fencing, cottages |

| Type 7 | Perfusion Pile | 1000 / 1300 / 1500 | 76–121 | 3.0–4.0 | Universal | — | — | — | Solar foundations, wood housing, ads |

| Type 8 | Tube Pile | 660 / 800 / 1200 | 76–121 | 3.0–4.0 | Universal | — | — | — | Solar structures, billboards, fences |

| Type 9 | Embedded Pile | 1300 / 1600 / 1800 | 76–121 | 3.0–4.0 | Clay, Gobi, Gravel | 22 | 20 | 9.6 | Solar plants, fencing, signage |

| Type 10 | Sand Area Embedded Pile | 1600 / 2000 / 2500 | 76–121 | 3.0–4.0 | Sandy Soils | 24 | 34 | 105 | Solar in sandy zones, ad signage, fences |

📐 Regular Sizes of Helical Piles (Customized Acceptable)

✅ Standard Round (Flange) Type

| Specification | Body Weight (kg) | Flange Weight (kg) | Blade Weight (kg) | Total Weight (kg) |

|---|---|---|---|---|

| 800×48×2mm | 1.81 | 1.50 | 0.30 | 3.61 |

| 800×60×2mm | 2.29 | 1.50 | 0.50 | 4.29 |

| 800×68×2mm | 2.60 | 1.50 | 0.50 | 4.60 |

| 800×76×2mm | 2.92 | 1.50 | 0.70 | 5.12 |

| 1000×48×2mm | 2.27 | 1.50 | 0.30 | 4.07 |

| 1000×60×2mm | 2.86 | 1.50 | 0.50 | 4.86 |

| 1000×68×2mm | 3.26 | 1.50 | 0.50 | 5.26 |

| 1000×76×2mm | 3.65 | 1.50 | 0.70 | 5.85 |

| 1200×48×2mm | 2.72 | 1.50 | 0.30 | 4.52 |

| 1200×60×2mm | 3.43 | 1.50 | 0.50 | 5.43 |

| 1200×68×2mm | 3.91 | 1.50 | 0.50 | 5.91 |

| 1200×76×2mm | 4.38 | 1.50 | 0.70 | 6.58 |

| 1200×76×3mm | 6.48 | 1.50 | 0.70 | 8.68 |

| 1400×76×2mm | 5.11 | 1.50 | 0.70 | 7.31 |

| 1400×76×3mm | 7.56 | 1.50 | 0.70 | 9.76 |

| 1600×68×3mm | 7.69 | 1.50 | 0.50 | 9.69 |

| 1600×76×2mm | 5.84 | 1.50 | 0.70 | 8.04 |

| 1600×76×3mm | 8.64 | 1.50 | 0.70 | 10.84 |

| 1600×89×3mm | 10.18 | 1.50 | 0.90 | 12.58 |

| 1800×76×2mm | 6.57 | 1.50 | 0.70 | 8.77 |

| 1800×76×3mm | 9.72 | 1.50 | 0.70 | 11.92 |

| 2000×76×2mm | 7.30 | 1.50 | 0.70 | 9.50 |

| 2000×76×2.75mm | 9.93 | 1.50 | 0.70 | 12.13 |

| 2000×76×3mm | 10.80 | 1.50 | 0.70 | 13.00 |

| 2000×76×3.5mm | 12.51 | 1.50 | 0.70 | 14.71 |

| 2000×89×3mm | 12.72 | 1.50 | 0.90 | 15.12 |

| 2000×89×3.5mm | 14.76 | 1.50 | 0.90 | 17.16 |

| 2500×76×3mm | 13.50 | 1.50 | 0.70 | 15.70 |

| 2500×76×3.5mm | 15.64 | 1.50 | 0.70 | 17.84 |

| 2500×89×3mm | 15.91 | 1.50 | 0.90 | 18.31 |

| 2500×89×3.5mm | 18.45 | 1.50 | 0.90 | 20.85 |

✅ Standard U Type

| Specification | Body Weight (kg) | U Head Weight (kg) | Blade Weight (kg) | Total Weight (kg) |

|---|---|---|---|---|

| 800×48×2mm | 1.81 | 1.00 | 0.30 | 3.11 |

| 800×60×2mm | 2.29 | 1.00 | 0.50 | 3.79 |

| 800×68×2mm | 2.60 | 1.00 | 0.50 | 4.10 |

| 800×76×2mm | 2.92 | 1.00 | 0.70 | 4.62 |

| 1000×48×2mm | 2.27 | 1.00 | 0.30 | 3.57 |

| 1000×60×2mm | 2.86 | 1.00 | 0.50 | 4.36 |

| 1000×68×2mm | 3.26 | 1.00 | 0.50 | 4.76 |

| 1000×76×2mm | 3.65 | 1.00 | 0.70 | 5.35 |

| 1200×48×2mm | 2.72 | 1.00 | 0.30 | 4.02 |

| 1200×60×2mm | 3.43 | 1.00 | 0.50 | 4.93 |

| 1200×68×2mm | 3.91 | 1.00 | 0.50 | 5.41 |

| 1200×76×2mm | 4.38 | 1.00 | 0.70 | 6.08 |

| 1200×76×3mm | 6.48 | 1.00 | 0.70 | 8.18 |

Usage Application

| City & parks | Docking post & Trestle stand |

| Fencing system | Flag Poles & Banners |

| Garden & Leisure | Sheds & Containers |

| Solar power systems | Solar racking systems |

| Street lamp & wooden house | Road & Traffic sign |

Advantages and Applications of Helical Piles

Helical piles are an innovative foundation solution composed of three main components: a hot-forged steel shaft, a helical blade, and a connecting flange plate. They are widely used across construction, energy, and agricultural sectors due to their efficiency and versatility.

✅ Key Advantages

1. Superior Structural Performance

- Helical piles are installed by rotating them into the ground, which minimizes soil disturbance and enhances stability.

- The helical blade design provides excellent uplift resistance and anchoring strength, making them ideal for both compression and tension loads.

2. Fast and Convenient Installation

- No excavation, no concrete, and no soil disposal required.

- Can be installed in a variety of weather conditions—rain, snow, or frozen ground—with minimal equipment.

- Easy to remove, relocate, and recycle, supporting sustainable construction.

3. Cost-Effective

- Compared to traditional concrete foundations, helical piles reduce labor, materials, and project duration.

- Simple installation requires only positioning and driving, lowering overall foundation costs.

🔧 Common Usage Scenarios

1. Building Construction

- Temporary Buildings

Ideal for site offices, worker accommodations, and mobile structures. Helical piles offer quick deployment, easy removal, and minimal site disruption. - Small Structures

Suitable for landscape pavilions, watchtowers, gazebos, and garden structures. They provide stable support and structural integrity on uneven or soft terrain.

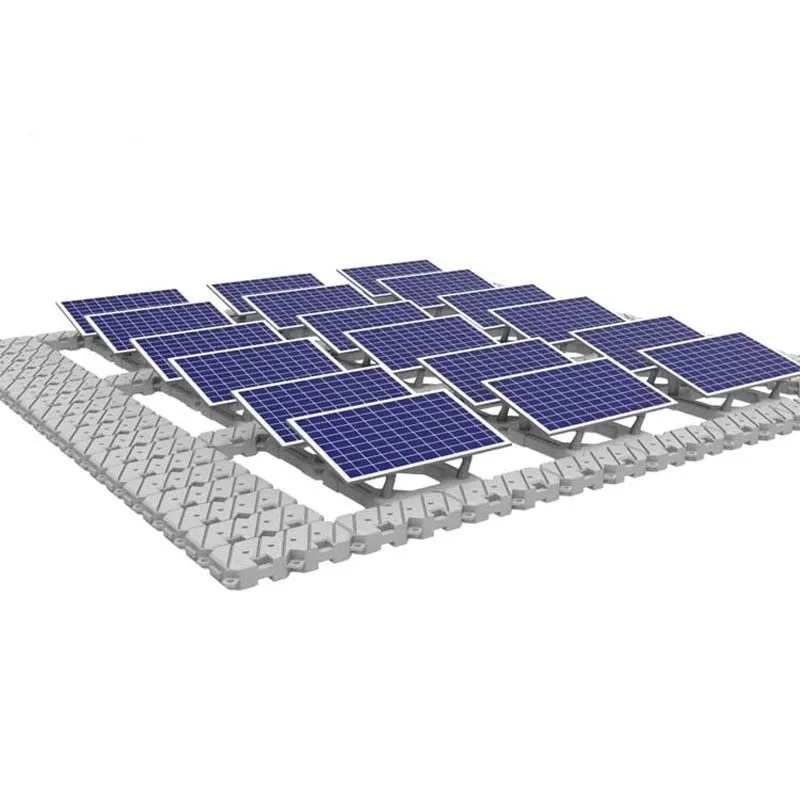

2. Solar Photovoltaic (PV) Installations

- Solar Power Plants

Widely used to secure PV mounting systems on the ground. Helical piles adapt to various soil types, speed up installation, and improve project timelines—especially in large-scale solar farms.

3. Transportation Infrastructure

- Traffic Signage and Safety Equipment

Used to anchor traffic signs, speed limit poles, and other roadside installations. Their stability ensures long-lasting support even in high-wind areas.

4. Telecommunications

- Communication Tower Bases

Provide a reliable foundation for telecom towers and antennas, particularly in remote or uneven terrain where traditional foundations are challenging to implement.

5. Agricultural Applications

- Greenhouse Foundations

Support greenhouse framing structures on different land types, reducing construction time and cost for agricultural operations. - Livestock Fencing

Combine with metal mesh fencing to create strong, fast-built enclosures for animal containment or land demarcation.

Helical piles are a sustainable, flexible, and efficient foundation solution for a wide range of industries. Their structural benefits, ease of installation, and reduced environmental impact make them a preferred choice for modern construction and renewable energy projects.

도움말 센터

질문이 있으신가요? 이 질문과 답변을 확인해 주세요.

Firstsolar는 80 명 이상의 숙련되고 숙련 된 근로자가있는 자체 공장을 보유하고 있으며 생산 라인은 높은 표준을 엄격하게 준수하며 품질 관리 검사를 매우 중요하게 생각합니다.

물론 최고 수준의 생산 엔지니어, 기술자 및 R&D 팀은 8년 이상의 경험을 바탕으로 고객에게 혁신적인 디자인과 신뢰할 수 있는 솔루션을 제공합니다.

예, Firstsolar는 10 년 이상 OEM 서비스, 디자인 서비스 및 구매자 라벨 서비스를 제공했습니다.

예, Firstsolar의 제품은 lSo, sGS, TUV 및 AS/NZS 1170.2의 인증을 받았습니다.

실제 주문 수량과 특별한 요구 사항에 따라 다릅니다. 일반적으로 1~2주 정도 소요됩니다.

총 금액이 US$5000 미만인 경우, 100% 선불, 총 금액이 US$5000 이상인 경우 30%T/주석 선불이 필요합니다.