-

2103 Kamer NO.322 Xinggang One Road, Haicang District, Xiamen Fujian, China

How to Choose the Right Screw Piles for Solar Mounting in General Regions

In the construction of mega-solar facilities, the speed of pile driving largely depends on the equipment used. The quality of screw piles also affects the lifespan of the solar mounting system, so knowing how to distinguish good piles from poor ones is essential.

This guide will walk you through the process of identifying good versus bad screw piles, the expected lifespan of screw piles used in solar PV installations, and the optimal installation methods for mega-solar facilities.

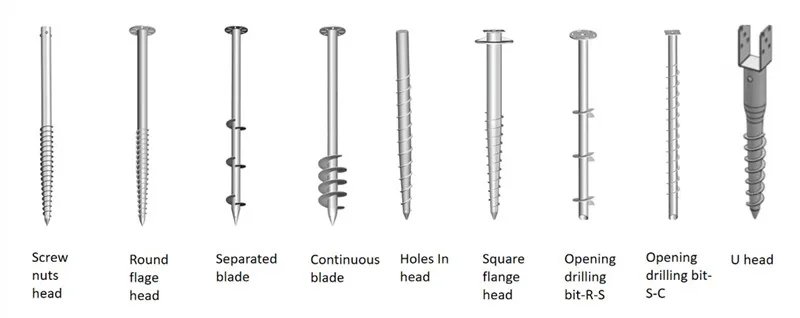

Check Before Pile Driving: How to Identify Good vs. Bad Screw Piles

The quality of the screw piles you use will significantly impact the construction process. It’s essential to choose “good piles” by considering the following points:

- Pile Thickness

- Thicker piles typically provide more strength, even when the ground is relatively solid. This ensures better performance over time.

- Galvanization Process

- Steel piles are prone to corrosion, but if they are adequately galvanized, they will benefit from superior corrosion resistance. If the galvanization is damaged, it’s advisable to apply cold zinc-rich paint or epoxy-based rust-proof coatings, especially for areas with high corrosion potential.

- Deformation or Damage

- Deformation is a common sign of inferior piles. Look for any irregularities in the screw section or missing threads. Sometimes, issues might not appear during installation but can surface when the piles are being pulled out later.

Lifespan of Screw Piles for Solar PV Installations

The lifespan of screw piles is primarily determined by the thickness of the galvanization coating, as well as the soil conditions. In general, the lifespan of screw piles with galvanized coatings is estimated as follows based on corrosion rates in different environments:

- Urban Industrial Areas: Average corrosion rate of 9.3 g/m²/year, lifespan of about 53 years.

- Rural Areas: Average corrosion rate of 4.5 g/m²/year, lifespan of about 110 years.

- Coastal Areas: Average corrosion rate of 11.1 g/m²/year, lifespan of about 45 years.

Typically, screw piles with molten zinc coatings can last up to 50 years, depending on the local environment.

For ground-mounted systems, consider using C-steel ground mount with screw pile foundation or aluminum ground mount with screw pile foundation to ensure longevity and performance.

Optimal Installation Methods for Solar PV Screw Piles

The installation method for screw piles varies depending on land conditions. Typically, land surveying, ground improvement, and weed control are necessary before pile driving. The installation of screw piles also requires certain considerations:

- Land with Obstructions: If there are underground obstacles, excavation tools such as Eco-Probe can be used before installing screw piles.

- Concrete-Covered Land: Use a backhoe to break the surface layer before installation.

- Loose Soil: Strengthen the ground with solidifying agents before installation.

- Slope Land: Special pile-driving machines are suitable for sloped terrain.

If you’re looking to optimize installation speed and reduce costs for your solar PV projects, consider using specialized heavy machinery that ensures efficiency, such as Gayk pile drivers or the versatile Bobcat machines.

Progression of Screw Pile Installation with Heavy Machinery

For screw pile installation, specialized tools are required. Heavy machinery such as backhoes with auger attachments are commonly used to ensure precise pile installation.

To install screw piles:

- Attach an auger to the backhoe.

- Use a level to ensure the piles are installed vertically.

- Slowly push the screw piles into the ground while continuously checking vertical alignment.

Each pile installation takes several minutes, depending on the soil type, depth, and machinery performance.

For high-speed installation, consider using efficient pile-driving machines. You can find reliable and versatile equipment recommendations from manufacturers and suppliers offering advanced heavy machinery suited for solar installations.

Why Choose Firstsolar for Your Solar PV Bracket Design Projects?

When planning screw pile installations for mega-solar facilities, the choice of equipment plays a crucial role in ensuring efficiency. For fast and reliable design and bracket solutions, you can trust Firstsolar for your solar PV mounting system projects. We specialize in providing high-quality solar mounting solutions that meet global standards and deliver optimal performance.

If you need professional design services or customized solar mounting systems, contact Firstsolar for expert consultation and reliable project support. Let us help you design and implement the best solutions for your solar PV projects.